Professional Flooring Repair Solution by FULADE Company

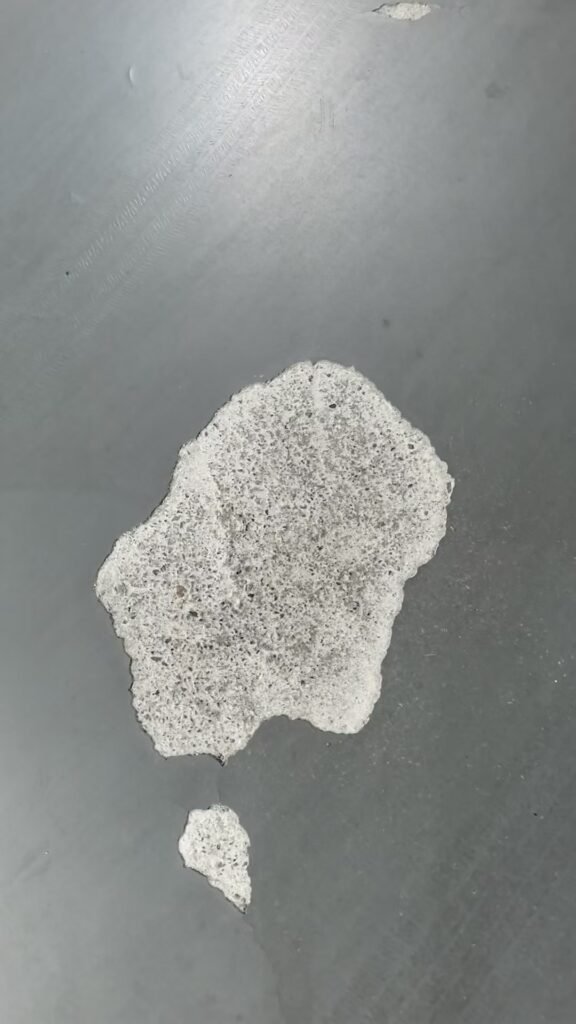

For painted floors that exhibit long-term blistering, cracking, or peeling after extended use, FULADE provides a specialized repair system with the following proven procedure:

Step-by-Step Process

Surface Preparation

Mechanically remove all damaged coatings using professional grinding tools

Diamond-polish substrate to achieve SSPC-SP13/NACE No.6 “Clean to Bare Metal” standard

Vacuum abrasive residues to ISO 8502-3 cleanliness requirements

Epoxy Primer Application

Apply solvent-free epoxy penetrating sealer (DFT: 50-80μm)

Key characteristics:

0.3-0.5% chloride permeability

3.5MPa tensile adhesion (ASTM D4541)

Structural Reinforcement

Lay epoxy mortar system (1:3 quartz sand ratio) as load-bearing layer

Follow with epoxy putty knife coat (100-150μm) for perfect leveling

Performance Guarantee

4. Finish Coat Options

Option A: Single-coat self-leveling epoxy (1.2-1.5mm )

Option B: Double-layer system with:

Base coat: Conductively-grounded epoxy (for ESD requirements)

Top coat: Polyaspartic hybrid with 72° gloss rating

Abrasion Resistance: ≤0.02g

Chemical Resistance: 30+ days immersion in pH 3-11 solutions

Service Life: 8-10 years in heavy industrial environments