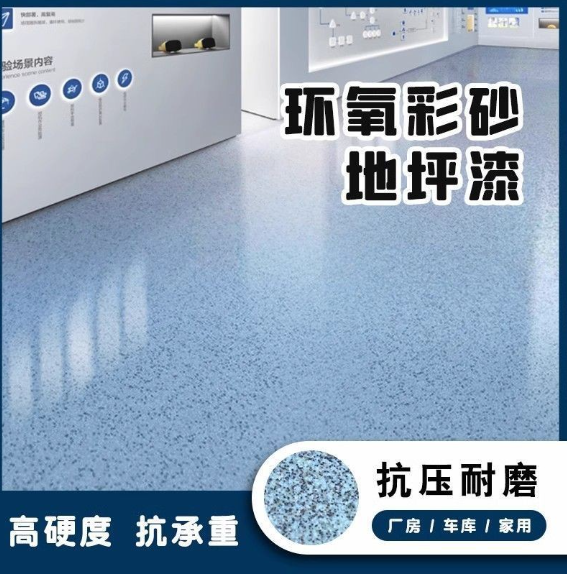

Epoxy Quartz Sand Self-Leveling Floor Coating: A Comprehensive Overview

Epoxy quartz sand self-leveling floor coating is a cutting-edge material widely used in industrial, commercial, and residential settings due to its durability, aesthetic appeal, and functional versatility. Combining the strength of epoxy resins with the decorative qualities of quartz sand, this flooring solution offers a seamless, high-performance surface suitable for high-traffic environments. Below is an in-depth exploration of its composition, applications, benefits, and installation process.

1. Composition and Technology

Epoxy quartz sand self-leveling flooring is a two-component system comprising:

Epoxy Resin: A thermosetting polymer known for its chemical resistance, adhesion, and mechanical strength.

Quartz Sand: Specially graded silica particles (0.1–1.2 mm) that enhance abrasion resistance and add decorative textures.

Self-Leveling Agents: Additives that ensure the mixture spreads evenly, forming a smooth, flat surface without manual troweling.

Pigments: Optional colorants for customization.

The blend achieves a balance between flowability and viscosity, allowing it to self-level while embedding quartz aggregates uniformly.

2. Key Features and Advantages

Exceptional Durability: Resistant to heavy loads, impacts, and abrasion, making it ideal for warehouses, factories, and garages.

Chemical Resistance: Withstands oils, acids, and solvents, suitable for laboratories, pharmaceutical facilities, and food processing plants.

Aesthetic Flexibility: Available in multiple colors and patterns (e.g., terrazzo-like finishes) to match interior design requirements.

Hygienic and Easy to Clean: Seamless surface prevents bacterial growth; ideal for hospitals, schools, and cleanrooms.

Anti-Slip Properties: The textured quartz sand surface enhances safety in wet or oily environments.

Fast Installation: Self-leveling properties reduce labor time compared to traditional epoxy flooring.

3. Applications

This flooring system is commonly used in:

Industrial Facilities: Manufacturing plants, logistics centers, and automotive workshops.

Commercial Spaces: Retail stores, airports, and exhibition halls.

Healthcare and Education: Hospitals, laboratories, and university corridors.

Residential Areas: High-end garages, basements, and modern living spaces.

4. Installation Process

Surface Preparation:

Clean and grind the substrate to remove contaminants and ensure adhesion.

Repair cracks and level uneven areas.

Primer Application:

Apply epoxy primer to seal the substrate and enhance bonding.

Mixing and Pouring:

Combine epoxy resin, quartz sand, and hardener in precise ratios.

Pour the mixture onto the floor, allowing it to self-level naturally.

Decorative Effects (Optional):

Add colored quartz chips or metallic pigments during pouring.

Curing:

Allow 24–48 hours for full curing, depending on temperature and humidity.